Applying chemicals to substrates through a foam medium produces many benefits over traditional application methods. More than 500 CFS installed systems testify to its proven performance.

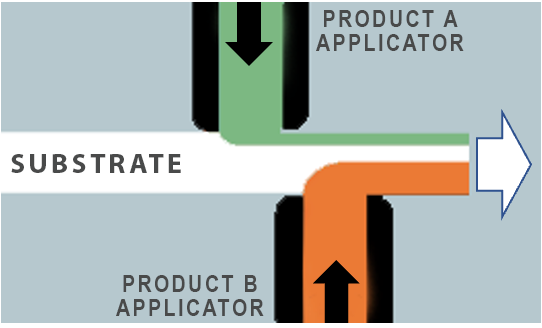

- Precision placement of chemicals to one or both sides simultaneously.

- Low wet pickup produces significant chemical and energy savings, without sacrificing performance. There is less water to evaporate and pre-drying is often eliminated.

- Application is independent of range speed. Speeds are often increased.

- Patented applicator provides uniform chemical distribution across any substrate width, resulting in improved product performance and/or quality.

- Inherent versatility offers product diversification opportunities.

CFS can be retrofitted to most existing ranges, providing cost advantages and increased versatility that can improve your product’s marketing potential